| ||

|

|

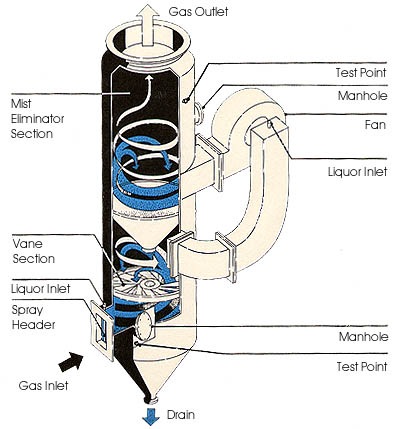

DYNAMIC WETTED FAN TYPE WF |

|

The Type WF scrubber is a highly efficient, econimical and dependable low pressure drop scrubber. The scrubber is particularly suitable for gas containing high dust concentrations with an average particle size of two microns or larger. The scrubber can handle high inlet temperatures and liquid streams containing solid matter. In operation, dirty gas passes through a spray zone located at the scrubber entrance. Particulate impinges against wetted curved surfaces of the lower cyclonic zone due to the tangential inlet connection. The gas swirls in an ascending spiral path through the vane section ahere larger dust particles are trapped in the descending water film and then discharged from the bottom cone. The gas containing finer particles rises upward and enters the intermediate fan located between the lower and upper cyclonic zone. The necessary amount of scrubbing liquid is introduced into the eye of the fan where intimate gas/liquor contact is obtained due to fan wheel rotation. This causes agglomeration of dust particles and entrapment into the scrubbing liquor droplets. The saturated gas passes into the upper cyclonic mist eliminator section where a tangential spin is imparted resulting in disengagement of the gas and liquor droplets prior to discharge from the scrubber top. |

| Dynamic wetted fan scrubbers can be constructed using carbon steel, stainless steel, specialty alloys or plastics. Units are available with capacities ranging from 600 to 100,000 cfm. Typical ApplicationsExaust gas cleaning in: |

|

|