| ||

|

|

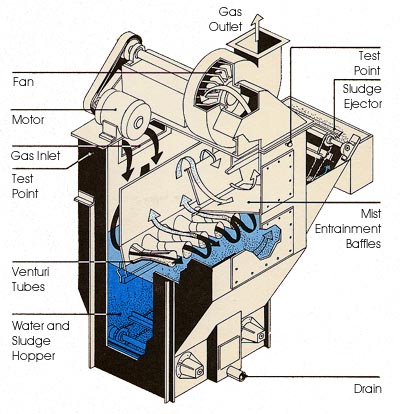

MULTIPLE VENTURI TYPE MV |

|

The Type MV scrubber is used for wet collection of fine, medium and greasy dust as well as large fibrous sticky material. It is a completely self contained unit incorporating a fan and optional sludge ejector. Water pumps or spray nozzles are not required with this design. In operation, dirty gas passes through multiple venturi tubes with water induced from a sump. turbulent mixing of the water and the high velocity gas stream results in efficient dust capture. The dust which is deposited on the walls of the unit, settles to the bottom of the tank which is then removed by a sludge ejector. Cleaned gas rises up and out of the unit through the entrapment baffles where complete removal of entrained water droplets takes place. MV scrubbers can be constructed from carbon steel, stainless steel, or specialty alloys. Units are available with capacities ranging from 600 to 55,000 cfm. |

| Typical Applications-Gas scrubbing in pulp & paper mills with liquor containing wood fibre |

|

|